When making any purchase, the buyer always pays attention to the packaging. Packaging containers protect the goods from mechanical damage, dust, moisture, etc. Quality and pleasant appearance the packaging gives the impression that the product being purchased is compatible. Is it possible to make money from this? The article will describe to you a business plan for packaging production.

Project Summary

Consider the example of a manufacturing business plastic containers for dairy products: sour cream, yogurt, etc.

IN Russian Federation production packaging materials, especially plastic containers, is very poorly developed. Packaging imported from abroad is expensive, and its cost can ultimately amount to up to half the price of the product. It follows that the niche for the production and sale of packaging in at the moment is developing and competition is relatively low.

You can open a business in any city where there are milk processing plants. This will ensure constant orders, because... The population constantly purchases dairy products.

Registration

To start your own business, you need to register as legal entity. For this purpose, registration as an individual entrepreneur or LLC is suitable. During the registration process, we select the taxation system (STS “income” or STS “income minus expenses”). We recommend the 2nd taxation option, because the tax base will be reduced by documented production costs.

You will need to develop or purchase ready-made specifications for your products.

For registration, it is better to contact a specialized organization. The total cost will be about 110 thousand rubles.

Search for premises

The equipment requires industrial equipment, which means it needs a 380V power supply. Because of this, you need to look for a building in an industrial area with connected communications. You will need a room of approximately 90-110 square meters. m. This area will house equipment and a warehouse. The monthly rent will be approximately 50-60 thousand rubles.

Purchase of equipment

Suppose you decide to open the production of plastic containers. To do this, you will need to buy a thermal packaging machine, a compressor, and molds for the products you will produce.

The initial investment will be 1,720,000 rubles.

If the machine model allows you to produce different containers, then in the future it will be possible to purchase additional molds to expand the range of products. This will help attract new customers. These could be pharmaceutical companies grocery stores, manufacturers of household chemicals, etc.

Purchase of raw materials

For production, polypropylene is required (the cost of 1 kg is approximately 60 rubles) and polyethylene (32 rubles per kg).

At least 3 tons of each type of polymer will be needed monthly. Thus, the cost of raw materials will be:

3,000 x (60 + 32) = 276,000 rubles.

Staff

For the stable functioning of the new enterprise, 9 workers will be needed (3 shifts of 3 people). We also need a cleaner, driver, designer, accountant.

Let's tabulate the expenses for staff maintenance

267 thousand rubles will be allocated for salaries every month.

Marketing and advertising

The launch of your project needs to be advertised. If you miss this moment, then the operating time client base can become a very long and difficult task. Advertising can be launched with signs, on the radio, on the Internet. It would be good to go to potential buyers and offer the product. To increase the likelihood of gaining clientele, we recommend developing a system of discounts or special conditions for regular customers.

If you immediately intend to offer large assortment products, then you can create your own website with a description of the product and promote it through contextual advertising in the vastness of the Runet. A high-quality website will cost about 40 thousand rubles, it will also need to be supported, which will cost about 10-12 thousand rubles. every month.

Financial plan

Start-up costs

Total: 1,985,000 rubles.

Monthly expenses

Each month the costs will be about 699,100 rubles.

Income

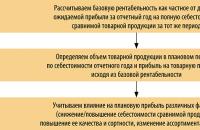

The average wholesale cost of plastic packaging for dairy products is 3 rubles. per piece (depending on the complexity of the design and size). Sales are carried out in batches of 2 thousand pieces. For the sustainable operation of the enterprise and achieving stable profitability, it is necessary to sell at least 300 thousand packages per month.

In this situation, net profit after taxes will be 150 thousand rubles, and profitability will be 18%. This figure can be considered small, but the plant’s capacity is sufficient to produce at least 1 million pieces of packaging per month. This will improve profitability in the future. If you organize your own collection of recyclable materials for work and minimize the costs of this income item, the result will be even higher.

Risks

Like any new businessman, you may encounter several significant problems:

- A small number of packaging forms in the assortment limit demand and complicate the search for customers. After some time of successful operation, it is planned to expand the range of offers.

- Low demand in the region. Are held in advance marketing analysis and preliminary discussions with managers of local dairies and small farms.

- The emergence of competitors. Developing a regular clientele, fulfilling delivery plans, constantly working to expand sales markets.

In the end

We have presented to your attention a business plan for the production of packaging with calculations. With a competent approach to starting your own business, production will lead you to a consistently high income.

In this article:

Packaging products made from cardboard and corrugated cardboard are today one of the most popular containers on the global and domestic market. The share of containers made from pulp and paper materials accounts for about 50% of the total volume of packaging consumed. This is explained by the fact that cardboard and corrugated cardboard are light in weight, characterized by high strength and low price. Therefore, paper packaging is used not only as a shipping container, but also as an individual wrapper.

Due to the constant increase in demand for paper packaging, many entrepreneurs are interested in how to organize industrial production of paper packaging from corrugated cardboard and cardboard? In order to answer the question posed, it is necessary to become familiar with the manufacturing technology of corrugated cardboard and cardboard, analyze the production of cardboard packaging and organizational details in opening an enterprise, and also draw up a detailed business plan.

Corrugated cardboard manufacturing technology

Before starting the production of corrugated cardboard, rolls of paper and cardboard intended for corrugation are placed in a room in which the air temperature should be more than 15 ° C. During the day, the process of conditioning should be carried out.

After this, the rolls are fixed on a rolling machine (unwinding machine) and then the prepared paper and cardboard are supplied to heating cylinders and intermediate rollers. This equipment heats and moistens the paper. Thanks to this operation, the glue penetrates better into the paper and ensures reliable adhesion to the cardboard.

Next, the production of corrugated cardboard is carried out on a corrugated press. On this equipment, the paper passes between corrugated rollers, the temperature of which is about 180 ° C. As a result of processing, a wavy layer of a certain profile is formed.

After this, the corrugated paper is placed in a glue-applying machine, where an adhesive film is applied to one side using a glue roller. The amount of glue can be adjusted using a dosing shaft. Next, the corrugated layer is combined with flat cardboard and processed by a pressure roller, resulting in a two-layer corrugated cardboard. This operation can complete the production of corrugated cardboard.

If three-layer corrugated cardboard is needed for the production of containers, then the two-layer corrugated cardboard is transported to a storage bridge, and then to a gluing machine. This equipment applies glue to the other side of the corrugated paper.

Finally, the corrugated cardboard is moved to a drying unit where it is glued and dried. The drying process can be carried out using electricity and steam or drying plates. During this operation, moisture is removed from the corrugated cardboard and the adhesive hardens.

After this operation, it is transported to the cooling part of the automated line. The cooling and drying process determines the characteristics of corrugated board.

The corrugated cardboard sheets are then fed into the department longitudinal-cross cutting, where it is cut and cut using circular knives. The cutting operation is very often combined with compaction. As a result of these operations, scoring lines are formed, thanks to which bending of sheets.

Finally, the corrugated cardboard is cut into sheets of specified parameters. The sheets are subsequently formed into corrugated cardboard packaging.

Equipment for the production of corrugated cardboard and packaging

A corrugated board production plant must have two lines:

- Corrugated cardboard production line;

- Line for the production of corrugated cardboard packaging. A modern corrugated cardboard production line must include a complex of high-performance automatic and semi-automatic equipment.

Corrugated cardboard and packaging production lines from TRANSPACK (China) are in great demand on the Russian market.

Therefore, for a novice entrepreneur, it would be advisable to purchase the “WJ-120–2200 D 1” line, the maximum speed of which is 120 m/min and the maximum blade width is 2200 mm.

To fully equip the plant, it is necessary to purchase a line for the production of corrugated cardboard packaging of the YKM-SB 3 series from the TRANSPACK company, which includes a set of machines for processing sheets and producing boxes of various sizes. The maximum productivity of automatic box production lines can be no more than 6,000 packages per hour.

The TRANSPACK line includes the following list of main and auxiliary equipment:

- Feed table;

- 3 pcs. printing sections;

- Slitting and scoring section;

- Rotary die cutting section;

- Automated sheet stacker;

- Automated folder-gluer;

- Scoring and cutting machine;

- Mini-slotter;

- Packing table;

- Waste paper press;

- Dissolver for glue production;

- Measuring instruments.

Taking into account the price level for equipment for the production of corrugated cardboard and packaging in 2013, capital investments for the purchase of lines will be at least 98 million rubles.

Cardboard production technology

Cardboard production is carried out as a result of a technological process that includes the following stages:

1. Preparation of raw materials includes a number of operations:

- The waste paper is dissolved in a pulper.

- cleaning waste paper from large ingredients, which is carried out using a high-concentration vortex cleaner.

- Additional dissolution of the purified mass is carried out in a pulsation mill.

- fine cleaning.

Next, the mass enters the composite pool, where rosin glue, starch and alumina are added to its composition. Finally, the paper pulp undergoes repeated fine cleaning using knot catchers and vortex cleaners.

2.Cardboard making. The paper pulp is fed to special machines, where the substance is dehydrated, pressed, and dried. As a result of these operations, a cardboard sheet is formed. Finally, the recycled paperboard is passed through the rollers of a machine calender, where the sheets are flattened under high pressure.

The finished cardboard is wound onto a tambour shaft and sent to a slitting machine. On this equipment, cardboard is cut into sheets. Ends process cardboard production.

Equipment for cardboard production

A cardboard production plant must have an automated line. Such a line should include a list of equipment for the preparation of waste paper and paper pulp:

- Pulper;

- Vortex cleaner, which allows you to remove heavy inclusions;

- Turboseparator;

- Pulsation mill;

- Disc mill;

- Vibrating sieve;

- Knotter;

- Vortex cleaners to remove light impurities;

- Mixer for waste paper.

A cardboard production line must also include a specialized machine that forms the cardboard web, dewaters it and dries it. A modern machine for the production of cardboard can produce 20-300 tons of products per day, the maximum width of the web can be 6000 mm.

To make cardboard you need the following raw materials:

- cellulose,

- waste paper

- or their composition.

It is known that to produce 1 ton of cardboard you need:

- 2 tons of steam;

- 1.1 tons of waste paper;

- 600-800 kW of electricity;

- 15-20 cu. m 2 water.

Technology for manufacturing paper packaging from cardboard and corrugated cardboard

The technology for manufacturing containers from cardboard and corrugated cardboard depends on the equipment available at the enterprise. Equipment for cardboard packaging is selected based on planned production volumes, nomenclature and box design.

The production process for manufacturing containers from cardboard and corrugated cardboard includes the following stages:

- Sheet cutting. To cut corrugated cardboard, enterprises use a cutting and scoring machine.

- Printing. Single-color or multi-color printing is applied at the flexographic station.

- Formation of blanks for boxes. Depending on the design of the boxes, different equipment may be used at this production stage.

- Gluing boxes. At this stage, the corrugated cardboard packaging enters the folder-gluer machine.

The box production machine operates in automatic mode.

Upon completion production process Cardboard products are formed into tied bundles, which are placed on a pallet. For further ease of transportation, the packs are bundled into pallets. At this operation, the production of cardboard boxes is completed.

Organizational subtleties in opening an enterprise

To organize an enterprise for the production of corrugated cardboard and corrugated containers, it is recommended to register the business as an LLC on common system taxation.

OKVED codes:

- 21.21 – “Production of corrugated cardboard, paper and cardboard packaging”;

- 21.11 – “Production of cellulose and wood pulp”;

- 21.12 – “Production of paper and cardboard.”

When manufacturing corrugated cardboard and packaging, it is necessary to adhere to the standards of GOST 7376-89, GOST 7420–89, GOST 7691–81.

Business plan for organizing an enterprise for the production of corrugated cardboard and packaging from it

The planned enterprise must include two production sites:

- For the production of corrugated cardboard;

- For the production of containers.

For the production of corrugated cardboard, the company plans to order all raw materials - paper and cardboard sheets - from OJSC Mari PPM. Delivery of raw materials will be carried out by rail and road transport.

Requirements for production premises

Production facilities in which corrugated cardboard and boxes are produced must have the following parameters:

- For the production of corrugated cardboard, a premises with an area of about 1400 m2 is required;

- It is necessary to allocate 1000 m2 for packaging production. In the production area, ventilation should be designed in accordance with SNIP 2.04.05–91, the fire safety system – SNIP 21–01–97. The temperature in production premises should be more than 18 ° C, and the relative humidity should not exceed 80%. Warehouse requirements for finished products and raw materials

Warehouses for storing packaging and raw materials must meet the following parameters:

- The warehouse area for corrugated cardboard must be at least 500 m2;

- The warehouse area for raw materials should be 500 m2;

- Warehouses must be protected from groundwater and sources of moisture;

- The indoor air temperature should be more than +5 °C.

Personnel requirements by category:

- Director;

- Chief accountant;

- 24 workers involved in the production process.

Total: 26 people.

The work of the company's employees should be organized in 3 shifts. The duration of one shift is 8 hours, 5 day work week.

Cost of corrugated cardboard and packaging

To calculate the cost of 1000 m2 of corrugated cardboard, we take into account the cost of raw materials for the manufacture of 1000 m2 of finished products. The cost of raw materials for making 1000 m2 of corrugated cardboard is: 3 rubles/m2 * 1000 m2 = 3000 rubles.

Total CC=3000 rubles.

Electricity costs:

To produce 1000 m 2 of corrugated cardboard, 1500 kW/h is consumed.

Total electricity costs (Se) will be: 1500 kW/h * 4 rubles. = 6000 rubles;

Steam costs for process operations:

The cost of 1 Gcal of steam is C = 161.32 rubles;

The specific rate of steam consumption for corrugated cardboard production is 4 Gcal;

Total costs for steam (St) will be: 161.32 rubles/Gcal * 4 Gcal = 645.28 rubles.

Expenses for paying wages to workers: 328,000 rubles per month, per year – 3,936,000 rubles.

Co (expenses for basic and additional wages for workers to produce 1000 m 2 of corrugated cardboard) = 400 rubles.

Payroll taxes – 140 rubles.

Expenses for maintenance and operation of equipment (Ccm): 4000 rubles per year;

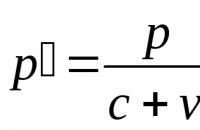

Calculation of the workshop cost of 1000 m 2 of corrugated cardboard: SSts = SS + Se + St + Co + SsmSSts = 3000 rubles + 6000 rubles + 645.28 rubles + 400 rubles + 4000 rubles = 14045.28 rubles

Workshop cost for the entire volume of corrugated cardboard produced per year: SStsg = 126,406,800 rubles.

Costs for manufacturing corrugated cardboard packaging

Let us assume that they amount to 2.5% of the workshop cost:

As a result of calculations, it was found that annual costs for corrugated cardboard packaging will be: 3,110,406 rubles, per unit. production (1000 m 2 of corrugated cardboard) costs will be 352.3 rubles.

General plant expenses: 6,220,500 rubles per year, per 1 unit. products – 706.5 rubles.

Expenses for renting premises: 1300525 rubles per year, for 1 unit. products – 152.1 rubles.

Total full cost will be: Sp (per 1000 m 2 of corrugated cardboard) = 15396.18 rubles, for the annual production volume the cost will be 862186.08 thousand rubles.

Revenue

The total volume of corrugated cardboard for the month is 5821200 m2;

The volume of corrugated packaging per month is 250,000 pcs. The average market cost of 1 m 2 of corrugated cardboard is 15 rubles.

Total revenue for the sale of corrugated cardboard will be: 5821200 m2 * 15 rubles/m2 = 87318000 rubles. The company plans to sell part of the corrugated packaging (50%) at a price of 20 rubles per piece, and the remaining part - 25 rubles per piece.

Total revenue for the sale of corrugated packaging will be: 125,000 pcs. * 20 rub. + 125000 pcs. * 25 rub. = 25000000 + 31250000 = 5625000 rubles.

Total revenue for the month: 92943 thousand rubles.

Revenue for the year will be 1,115,316 thousand rubles.

Net profit for the year will be: 1115316 thousand rubles – 862186.08 thousand rubles = 253129.92 thousand rubles, net profit for the month– 21094160 rubles.

Capital investments for the purchase of equipment amount to 98 million rubles.

At this monthly income level from production activities The payback period will be 5 months. Calculations showed that the organization industrial production corrugated cardboard and packaging is a profitable and profitable type of business.

Advantages of paper bags and sacks

In one of the articles we already discussed a business plan for the production of plastic bags. So why, along with such a popular product as plastic packaging, paper bags and bags do not fade and do not lose their relevance, being in demand among consumers and manufacturers?

The answer is quite simple. There are several advantages of such packaging.

Firstly, polyethylene, no matter how durable it is, is still not intended for storage certain types goods. For example, some building mixtures, or charcoal.

Secondly, the materials used to produce this type of product like paper bags are different from polyethylene production characterized by safety and harmlessness for environment during their production and disposal. And such an approach is not only important, it ranks first in importance at the state level. Even if not as much here as in Europe. Ecology, as well as safety for human health - important factor, which is gaining momentum and will soon greatly influence the entire production.

Thirdly, the materials themselves that are used to make paper containers are not that expensive, they are convenient and profitable to use, which of course attracts manufacturers.

Fourthly, if we talk about packaging food products, then paper bags are significantly superior in quality to plastic bags. They are able to retain food quality longer. Plastic packaging often leads to the loss of its original properties. For example, we can cite flour, coffee, as well as various spices, the share of which on the market is by no means small.

We must not forget about fast food outlets, where, due to their qualities and specificity of products, paper packaging bags are used for the end consumer.

Well, if you pay attention to marketing large companies, then you will notice that they take full advantage of the emphasis on the quality of paper packaging in order to promote the image component.

The result - the production of paper bags and sacks today is a rapidly developing and promising industry small business, which in the future will show not only stability, but also rapid growth.

Where are paper bags and sacks used?

The purposes for using paper containers are varied. There are a few of the most relevant ones:

- Used to maintain the safety of products from food and other industries.

- Cafes, restaurants, bars and any other food outlets use paper bags to package their food.

- Brochures for exhibition events and promotions of various types are also packaged in paper.

- Packed in paper bags and dry building mixtures, charcoal and a number of certain construction products.

- Paper is used in floristry and design.

- Gifts are also packaged in paper wrappers and bags. In this case, polyethylene will only spoil the appearance.

- Paper bags are used for storing and packaging compost and household products.

In addition to the above-mentioned sales areas, there are many more small branches, industries and enterprises that fully or partially use paper types of containers. Therefore, it will not be difficult for the manufacturer to find potential clients for your product.

Manufacturing technology of paper bags and sacks

Studying the manufacturing technology of your future product is the responsibility of every entrepreneur who will sell this product.

Here we will look at the main stages of making paper packaging, which will make up the entire production process. There are five such stages.

- The first stage is the formation of blanks for bags. The stage is simple. It involves creating a pipe out of paper. This pipe will pass through a special conveyor and be divided into separate packages.

You need to know that the first stage will also include the application of logos and other designs intended for the symbolism of the customer or manufacturer, if provided for by the project, to the blank pipe. The application of symbols itself can carry out various options, depending on the equipment used in the enterprise.

- The second stage is gluing and forming the bottom.

- The third stage is the production of a valve blank for special valve packages, if there is a process for producing packaging that will be closed or sealed.

- Next is the final gluing and pressing of the bags. This stage is intended for the convenience of further storage and transportation of the finished product.

- The last thing is the formation of packaging batches, which will include a certain amount of finished containers for further wholesale.

Various ways to print on paper packaging

Different printing techniques are used depending on the types of production. The most popular at the moment is offset printing. It is used for mass circulation.

Flexography is also a common method. But it is worth understanding that this option is used mainly by organizations that have already found their feet and want to further raise their prestige, because flexographic printing is much more expensive than offset printing.

In addition to flexography, silk-screen printing is also used. It is used for applying both single-color and multi-color images. But unlike previous methods, they are also used in the production of small batches of goods.

Embossing is an expensive method, and therefore the least popular among manufacturers. By the way, in addition to financial costs, you will need to expend manual labor, as well as buy expensive equipment. These factors are the reason why embossing is used exclusively to create gift wrapping and high-quality paper bags. Accordingly, the price finished product far from the market minimum.

Manufacturing and attaching handles to ready-made bags also increases the cost finished goods, as it complicates the production process and requires additional equipment costs.

Equipment for the production of paper packaging

Production equipment is selected based on what types of bags you will be producing. There are two types of paper containers - stitched and glued. Accordingly, the machines for producing such bags also differ.

The main characteristics of the machine equipment will influence its cost and initial investment. But also on the speed of production of goods, and therefore on the payback period. It is necessary to take into account the power of the machine, its productivity, packaging efficiency and the type of production line.

According to average statistics, the cost of the most ordinary machine starts from 200 thousand rubles. A modernized version of the equipment, which will be capable of producing multilayer paper, will cost no less than 450 thousand rubles.

Mixed type machines are much more expensive. As a rule, this is 800 - 850 thousand rubles. On the other hand, it is the mixed type machine, despite its high cost, that allows greatest success quickly recoup investments in production organization. The fact is that in addition to a larger number of packaging options, it will be able to provide you with good production speed, producing up to 210 blanks in two layers in one hour of work.

The best option, if you have investment, is to purchase a fully automated paper bag production line.

Additional equipment for the production of paper containers

Purchasing additional devices for quality production necessary. In addition to the above options for machine equipment, you will need other devices:

- Mechanism for multilayer stitching of paper products for stitching bags.

- You may also need a punching machine.

- Special paper loading device

- Hydromechanical press for copying finished products

- Printing machine with multi-color and monochrome printing

But additional devices are additional because production itself in its simplest form can be organized without them, investing only as the business develops. Everything will depend on your plans, goals and financial capabilities.

Premises and staff

The choice of premises when organizing the production of paper packaging has fairly flexible criteria, allowing you to choose from a wide range of areas available on the market. The main factors that should be the basis of the choice are that the premises must be equipped with water supply, sewerage and electricity supply.

And also, in no case should we forget about compliance with fire safety standards!

For the rest, you will guide yourself based on the dimensions of your equipment and what departments, in addition to the production premises, you will need for successful work.

For the full operation of your production line, three to four employees will be enough (at least at the initial stage), who will be involved in shifts. A shift work schedule will improve the efficiency of workers and eliminate machine downtime.

Recommendations for hiring workers are simple - they may not have specialized qualifications or specialized education, but experience working behind similar automatic production lines is highly desirable.

Cost

Basic financial investments to start a business will consist of:

- monthly payment for rented space

- the cost of equipment for the production of your final product - paper packaging.

Rent is difficult to predict in advance, but the selection of suitable premises and analysis of market prices for the area should be carried out at the business planning stage. Depending on the distance of the square from the city center and transport interchanges, the square and a number of other factors, the price will be added up. On average, the amount will be from 50 to 100 thousand rubles per month.

Equipment, as mentioned above, has an even greater range of prices, which depend at least on the performance and capabilities of the machine itself. If you plan to first create a small production base with a small volume, you can meet 600 thousand rubles.

If you are immediately focused on good volumes and stable production, then the amount of investment in equipment will not be below the limit of 900 thousand rubles.

The complete set of the automatic line will lead to a significant increase in the investment level at the initial stage and will cost 2 - 4 million rubles.

You will also need to take into account the salary fund. If your employees are not qualified, then the monthly expenses for wages for four employees with a shift schedule will be about 70 - 100 thousand rubles.

Here you can initially save money by hiring only two workers at the starting stage. In this case, expenses will be 30 - 40 thousand rubles per month.

In addition to the costs described, you will need to include general business needs and unplanned expenses in the expenses column. This is approximately 10 - 15 thousand rubles monthly.

Taxes on maintaining entrepreneurial activity will cost 30 - 40 thousand rubles.

Raw materials for making paper bags and sacks

When making paper containers, you can use any paper, which is good. You can also use paper made from recycled materials - waste paper.

But several types of material are used as standard - cardboard, efaline, coated paper, kraft paper, waterproof luxpack paper and artlibris.

To achieve good strength of the finished product, it is recommended to glue the paper in several layers, and in addition apply cross-gluing.

Income from the production of paper bags and sacks

The production of paper bags is considered a highly profitable activity. At proper organization workflows, the company’s profitability even in the first stages of work can reach 200 - 400 thousand rubles monthly.

Therefore, we can say that it will take about a year or two to cover all the company’s expenses and reach a net profit, which is quite a short time by the standards of organizing production from scratch.

For an illustrative scheme for calculating income, we will use certain prices. But you need to understand that in an unstable economic situation, they can constantly change.

If raw materials are purchased at a price of 35 thousand rubles per ton, and the paper consumption per bag is 0.09 kg, then the cost of one bag will be 3.15 rubles.

The cost of wages to one employee for the production of one package will be 0.05 rubles. Other costs are 0.03 rubles. In total, the initial cost of the package will be 3.23 rubles.

If the starting selling price is 10 rubles per package, then the revenue from one package will be approximately 6.77 rubles.

At a fully loaded production level, it is possible to achieve results of producing six thousand bags in one day. The quantity per month will be 132 thousand pieces of finished product.

Net profit with this calculation will be equal to 893.6 thousand rubles per month. But these are only theoretical calculations without taking into account the specific situation and individual factors.

Problems of organizing a paper packaging business

- As an entrepreneur, you will be interested in reducing production costs. Therefore, the main problem and task will be to find suppliers of inexpensive raw materials. And along with this task, the question of logistics will arise.

- When operating machines it is consumed large number electricity. Therefore, the initial expenditure on expensive equipment, which, among other advantages, boasts economical energy consumption, will most likely pay off in the future with great benefits.

- Finding distribution channels is not only a task at the initial stage of organizing a business. Such work must be carried out constantly so as not to lose the pace of sales and profits, as well as to develop.

Now in any store and even a small kiosk, goods are packaged everywhere, often by the manufacturer, but sometimes by the sellers themselves. In large stores, there are corresponding small workshops involved in packaging, for example, bulk goods, candies and other sweets. Prepackaged goods both look better and cost more, especially if the packaging is colorful. Our people are used to paying for unnecessary beautiful packaging.

In some stores, sellers themselves package, for example, candy. The saleswoman weighs on an electronic scale, a sticker with a barcode comes out, in principle this is also an option, but not in every store. This is not entirely suitable for small shops.

Packing bases have special equipment and areas for quick packaging. But they don't have such a wide range. Wholesale stores selling products have a large assortment, but as a rule they sell unpackaged goods or packaged goods from the manufacturer. They sell sugar in bags, sweets in boxes, etc.

Small shops and kiosks cannot afford a large assortment of unpackaged goods; for example, you cannot buy each type of candy in a box, since they will take a long time to sell and the fact is that they will be sold before the expiration date. And buyers want a large assortment and the opportunity to buy goods not in kilograms, but in smaller packages. For small entrepreneurs, a problem arises: it is impossible to ensure wide range, resulting in an outflow of customers.

Do you feel there is a niche for a food packaging business? We collect applications from small traders, purchase goods in bulk and package them in the quantities and volumes they need.

How does the mechanism of this business idea work? You need to buy a product at a wholesale price that you can package and pack in small packages.

You will also need an agreement with retail chains who will sell your product. Also, in addition to packaging own goods you can provide similar services for small supermarkets that want to have products with their brand logo.

It is best to pack seeds or peanuts. Although their cost is not great, they sell out very quickly. retail trade. You will be able to earn money consistently. You can also pack cereals or sugar, but then you will have to buy a larger machine and it will cost a little more. But there are still advantages in this business. This device can be operated by only one employee.

How to start your own packaging business?

There are two types of packaging: manual, which we have already described above; it is long and unproductive. But for starters, this may be suitable, don’t immediately purchase equipment for the second method, automated, in case the business doesn’t work out.

First, it makes more sense to start with manual packaging, establish connections, and earn some money. Understand what this business can bring. And then you can open an automatic packaging workshop. You can pack any product, both bulk and all kinds of cookies, sweets, etc. We need to establish a chain: wholesale centers - small shops and kiosks. And if you mark up 1 ruble per package, the dirty profit will be up to 300,000 rubles per month, which is exactly how many bags can be packaged on this machine.

Of course, you shouldn’t expect such volumes right away; you need to start, as we wrote above, with manual packaging, because maybe you don’t have so many small ones retail outlets those wishing to purchase packaged goods. Then you will only spend money on electronic scales, table and room rental. The most difficult thing here is to establish connections with small entrepreneurs; you will have to run around, conduct a whole series of negotiations, and interest them. You can attract them with goods for sale, and agree on a deferred payment.

Finally, a few tips.

1) The so-called “standing” packaging is better, not the “lying” one.

In stores, when the buyer takes it, the same one will be visible behind it, but as a rule, when the packaged product is lying, the buyer no longer sees the product.

2) There is more profit from a small package.

Take for example a bag of coffee with cream 3 in 1. Its cost is 7 rubles. What does it contain? The lowest quality cocoa, milk powder and sugar. There are specimens that you don’t even want to drink. Yes, and milk curdles in boiling water. However, these bags are used in great demand, especially in canteens. Let's break down the material component of one bag consisting of quality products. So, the weight of one bag is 20 grams. Now let’s calculate what we put in a glass of coffee for breakfast: 1 teaspoon of instant coffee weighs 10 grams, 1 teaspoon of powdered milk weighs 12 grams, granulated sugar - 10 grams. For many, one spoon clearly will not satisfy, and most people put in at least two, as evidenced by the very sweet 3-in-1 coffee drink. What happens? Our 3 in 1 bag should weigh 42 grams. This means that manufacturers save on coffee and milk, replacing them with regular sugar. Thus, 1 sachet of 3-in-1 drink takes 5 grams. coffee, 5 gr. milk powder and 10 gr. granulated sugar. At the wholesale base, a 100 gram jar of Nescafe classic coffee can be bought for 65 rubles, 250 grams of milk powder costs 20 rubles, 1 kg of sugar costs 28 rubles. Roughly, 1 kg. coffee costs 650 rubles, 1 kg. powdered milk - 140 rubles, 1 kg of sugar - 28 rubles. Thus, observing the proportions and taking 1 kg. coffee, 1 kg. milk powder, 2 kg of sugar and having spent 846 rubles on the components of the drink, we will receive 200 bags of 20 grams each with a total cost of 1,400 rubles. The difference is 554 rubles. If we take into account that the manufacturer’s components are 10-15% lower than in retail, the costs of components can decrease by another 10%, i.e. roughly by 85 rubles, and then the difference in price will already be 639 rubles. Sorry, this is almost a 100% profit when using high-quality ingredients that none of the manufacturers put in existing drinks.

The most important thing left is to find an acceptable “cheap” way to package the resulting drink. This is where innovation or know-how is required. By minimizing these costs, you can get very good profitability. But the existing packaging equipment is not affordable for a novice businessman, and such speed is not required, since for home business A net income of 50 - 70 thousand rubles is considered very good, and this is only 200,000 bags per month with a total weight of 400 kg. What a trifle, packaging 8 bags of sugar within 30 days and getting 50,000 rubles for it. Only 14 kg will have to be packaged per day. Even if half of this amount is spent on packaging and transportation, 1 thousand dollars a month is not a bad income.

3) The thicker and more beautiful the packaging material, the more premium the product appears in the eyes of the buyer.

Almost any person purchasing an expensive gift for a friend, colleague or acquaintance is ready to invest several hundred rubles in the purchase of original gift packaging!

How is cardboard packaging produced?

Production of cardboard packaging: economic feasibility of business + general information about products + marketing research + organizational issues+ development stages + recommendations for raw materials + requirements for premises, personnel + technical equipment enterprises + sales features + profitability.

Where to start making gift wrapping?

To open a mini-production enterprise, you must first conduct marketing research.

This will help you choose your business specialization!

✔

A win-win option is considered to be the release of products intended for women (jewelry, phones, etc.).

Of course, on the eve of the holidays, the business concept will need to be adapted to the needs of consumers:

✔

So, on Valentine's Day, it makes sense to release it in the shape of a heart.

✔

Before New Year holidays Several batches should be made for toys, artificial Christmas trees and other holiday attributes.

How much money do you need to start a gift wrapping business?

✔

To launch such a project, an initial investment of about 400,000 rubles will be required.

✔

To operate the enterprise, you will need to rent a production space with an area of at least 500 square meters

✔

About $100,000 will need to be invested in the purchase of a high-precision technical equipment, intended for the production of gift packaging from plastic, cardboard and other materials.

What equipment to choose for making gift wrapping?

The production line will consist of such elements as:

or

An enterprise producing packaging products must have designers, specialist technicians, operators, sorters, and general workers on staff!

- a business direction that, if managed correctly, will bring decent profits to the entrepreneur. This is due to the truly high demand for production results, i.e. finished products.

Take a look at one of the major industrial sectors of each state, namely. You will see that over the past 10 years, containers have become a priority product in the national economy.

Packaging consumption is high, especially in industrialized countries, such as Russia. 78% freight transport occurs using cardboard containers. This means that every year the need for pallet containers is growing by at least 10%.

It is interesting that the Russian Federation is characterized by a significant predominance (12 times) of imports over exports. Those. Hundreds of millions of dollars, which would be enough to establish and develop domestic industrial packaging production, are spent on the purchase of imported packaging products of various types.

The most difficult stage in organizing such a micro-business is finding sales channels for gift packaging:

Of course, creating and promoting a high-quality website will require certain expenses (about 700 thousand rubles), however financial result The operation of the enterprise will improve within a few months.