Modern production so automated that in order to, say, produce vehicles, toy cars, vacuum cleaners, kitchen utensils and others, just press a button and the creation process is activated. Have you ever wondered how this miracle technology works? The proper operation and safety of the automatic construction equipment is ensured by every detail that is included in its package: bolts, nuts, bushings, couplings, etc. All these components are the result of the hard work of a human turner, from labor activity on which scientific and technological progress as a whole depends.

Profession turner

A lathe is a specialist who is engaged in mechanical processing of parts from a variety of hard materials (metal, plastic, wood, etc.) through mastering the skills of working on a lathe.

The word “turner” itself has Proto-Slavic roots and in translation means “to sharpen”, “turning”. If you look at it, the beginnings of this profession appeared in ancient times, when people realized that the necessary part could be made from any material.

A turning specialist works on machines, which, depending on the type of material used, can be metalworking or woodworking.

Based on the fact that lathes are different types, and the work that can be performed on them is different, there are several specializations:

- carousel turner;

- head turner;

- revolver turner;

- turner-sharpener;

- lathe-borer;

- turner-miller;

- universal turner.

It is worth noting that the responsibilities of a turner include not only working on machines, but also with workpieces, selecting the best ones and rejecting them, preparing the workplace and cleaning it after completion of the labor process.

The carousel turner is

The mechanical engineering industry cannot imagine its existence without such a specialist as a rotary turner. He specializes in the manufacture of cylindrical and cone-shaped objects, on the surface of which there are various holes, grooves, and one or another type of thread. Such a specialist works on a rotary machine operating from high voltage. The unit contains metal parts that are hot and rotate quickly. Therefore, special attention is given to compliance with safety regulations.

Operating principle: part processing is carried out through the interaction of a rotating workpiece and cutting tools, which move at a given speed and at an appropriate angle.

A carousel turner is a specialist whose responsibilities include:

- processing of workpieces complex type on specialized equipment;

- grinding with a high degree of precision;

- boring holes;

- turning surfaces shaped like a cylinder or cone using several cutting tools;

- cutting various types of threads;

- processing of workpieces by plasma-mechanical method;

- processing of rolled solid wheels according to clearly established dimensions after running in.

Lobovik

Front turner - who is he? Such a specialist works on turning machine tools. The responsibilities of the windshield mechanic include processing of bodies and semi-finished parts. The work uses heat-resistant stainless steel). Such specialists are indispensable in aviation production.

Revolver turner

A turret lathe operator is a worker who maintains turret lathes and specializes in processing parts of various levels of complexity depending on the level of professionalism. Processing involves the use of cutting tools and various devices.

What does a revolver do? It cuts external and internal threads of various shapes (double-start, rectangular, semicircular, sawtooth, single-start, trapezoidal); performs complete processing of screws for micrometers; trims, drills, bores and taps caliper nuts with a cutting length of more than 50 mm; processes discs for universal chucks of metalworking machines; grinds and bores benches and ball joints with a radius of more than 100 mm according to a template; processes cylindrical gears of various diameters and bearing shields.

Features of the profession of a lathe-borer

A boring lathe is important person at the enterprise. Its main task is the processing of elements - blanks, from which various parts are subsequently assembled. The raw material can be wood, metal, plastic, etc.

The specialist also determines the depth of the details. A specific one is selected depending on the individual characteristics (properties) of the raw material and the parameters of the cutter. The boring machine fixes the part and begins processing it. The output should be a workpiece, the dimensions of which fully correspond to the specified parameters indicated in the drawing and in terms of reference. Only in this case the work of a lathe-borer is considered productive and effective, but otherwise it is useless work.

In his work, the boring machine uses not only the machine mechanism, but also complex measuring instruments. The latter include indicators and micrometers.

Another variety

A turner working on a milling machine is a milling machine operator. It processes hard materials (metal, wood, etc.) through the operation of a cutter. IN production process In any factory or enterprise, this employee plays a key role.

Tasks performed by a turner:

- operations related to processing parts according to ordered parameters;

- systematic monitoring of the operation of machine tools;

- reconfiguring the machine to produce other products.

Advantages of the profession

1. Demand. Today, there is a shortage of specialists in the turner profession, which creates a high demand for turning specialists among employers.

2. A turner is a highly paid job. The reason is demand and difficult working conditions. In addition, the specialist himself can control his salary. As a rule, the piecework method of remuneration is used, which allows you to earn as much as you need.

3. Realization of creative potential. The profession of a turner is ideal for creative people, as it allows them to express themselves as creatively as possible. The labor process, which consists of various types of processing of blanks and parts, is compared to art.

Disadvantages of the profession

1. Difficult working conditions. First of all, this concerns the complex design of turning equipment, the operation of which requires exceptional compliance with safety regulations. Also, the result of any labor process on the unit is production waste: hot metal shavings, sawdust and other substances, the contact of which with the skin will cause burns or injury. In addition, for safety reasons, the turner must work in special clothing made of thick fabric, which he has to wear in both heat and cold.

2. Monotony. It manifests itself in the monotony of the work process, performing the same actions regularly.

3. There is no opportunity for career growth. A turner is a job that does not imply any big career ups. However, systematic professional development and advanced training is mandatory. To some extent, this disadvantage is compensated by good wages.

What should a turner be like?

The future turner must understand that he has chosen an interesting profession, but not an easy one. Most of working day a turner spends his time standing on his feet in a relatively uncomfortable position, so the first thing a turner must have is good health and physical endurance.

In addition, a turner must also have a number of personal characteristics, including:

- accuracy;

- ability to concentrate;

- concentration;

- responsibility;

- developed imagination in space;

- the ability to think visually and effectively;

- technical mindset;

- developed ability to measure and determine dimensions “by eye”;

- diligence and diligence;

- excerpt;

- perseverance.

What knowledge is needed to take this position?

A turner is a technical profession that requires knowledge of physical laws, features chemical composition processed metal structures and parts. He produces parts according to clearly designed and specified parameters in the drawings, so all turning specialists are distinguished by their inherent unique ability. A turner must know the structure of the machine on which he works, the properties of the materials used.

The ability to plan the turning process is also a key requirement.

Medical contraindications

Where to study?

There are two ways to become a turner:

- graduate from a secondary specialized institution, which is available in the cities of the Russian Federation;

- get a job in production as an assistant to a professional turner, who will be a teacher-mentor.

But still, priority is given to the first method of obtaining a profession, which involves completing a full course of study on the basis of specialized technical schools and colleges.

Drill, cut, countersink and calibrate - the words are clearly understood by a turner. Since the profession of a turner is inexorably linked precisely with these properties of working on wood, metal, plastic and plexiglass. In other words, the profession of a turner is associated with the processing of parts that are used in a wide variety of fields. A turner is a purely male job that requires serious strength and endurance, although in some countries of the world you can still find a woman turner. The profession of a turner is divided into several specializations and categories. The work is carried out using a lathe. You can become a turner after 9th grade by enrolling in college, you can master the profession without studying anywhere, having received initial specialization in production, or you can go to turner courses to learn both practical and theoretical basis turner profession.

What does a turner do? What does a turner do?

Turner - the real one working profession. Often at high temperatures, a specialist turner processes parts made of wood, metal, plastic, resin or plexiglass every day. The higher the qualification, the more work the turner does. Depending on his specialization, a turner does a little various activities. There are 5 of them in total: turner-borer, turner-universal, turner-sharpener, turner-carousel and turner-revolver. The level of his qualifications depends on what the turner does. The very first in rank is a novice turner of the 2nd category, and the last is the 6th. The higher the rank, the higher the level of knowledge, qualifications and the more the turner does. At the same time, the level of qualification affects not only what a turner does, but also how much he receives.

How much does a turner earn?

Despite the fact that the work of a turner cannot be called simple, unfortunately, entry-level specialists cannot boast high level wages. The entry point into the profession in the regions is the figure of 10,000 rubles. But a turner who only does work in the second category is not a turner, but a beginner, so from the 2nd category to the next it only takes about a year - then you can improve your qualifications to the 3rd category. A 3rd category turner will earn a little more, but he is still far from the income of a 6th category turner, who can claim 30,000 on average in the labor market today when working in general admission enterprises. A turner who works for the benefit of the defense industry and at closed enterprises can afford to earn 100,000 rubles and more. Everyone has such opportunities - it is only important to improve your rank and practice.

Features of the turner profession

Turner - purely male profession. What a turner does is practically impossible for any representative of the fair sex to do. Working as a turner means constant growth, an increase in rank and income, but a fall is also possible. If a turner does not do his job well, he may be demoted and in order to move up, he will have to prove his professionalism again from the previous level. Working as a lathe requires exposure to high temperatures and the ability to operate a lathe. Today people have entered the profession of turner and modern technologies, which allow processing parts in automatic mode, but the filigree work of a real turner still cannot be replaced.

Hello! And so today, what kind of profession is a turner? This is the topic of my post. From the article you will find out what kind of turners there are and how popular they are this specialty. After all, standing at the helm of a lathe is not as easy as it might seem if you watch it from the side.

Profession turner, what kind of profession?

So who is this person? First of all, a turner is a specialist worker who is fluent (or almost 🙂) in the art of working on a lathe. A worker in this profession performs the following operations:

- Treats external cylindrical surfaces.

- Cuts threads (with a lathe, dies, etc.)

- Sharpenes shaped surfaces.

- Drills holes that are located on the axis of the workpiece.

- Countersinks holes.

- He goes over them with a sweep.

- Trims the ends of various bodies of rotation.

- As well as conical parts with different angles.

Still very important point is that a worker of this profession must be able to select cutting modes before starting work, such as, and also select necessary tool to perform one of the above operations.

What types of turners are there?

And so turners, depending on the equipment they work on and the operations they perform, fall into the following areas:

Works on universal lathes or screw-cutting lathes type 16K20. We also note that the station wagon speaks for itself :) Here's the machine he works on:

The boring machine mainly performs the operations machining on jig boring machines. His work is associated with high precision not only of the processed surfaces but also of their location in the part. Here's the hardware it works on:

Carousel turner.

Works on a rotary lathe. There is one feature here, namely, the main movement is performed by the machine table, which is the opposite of the 16K20 universal lathe. Here is the actual machine he works on:

Revolver turner.

A turret machine is characterized by the presence of a turret head into which several cutting tools are fixed. This manipulation allows you to quickly and easily perform a wide range of turning operations. Well, here’s the actual turret lathe:

What education and knowledge is needed to work as a turner?

In order to obtain the profession of a turner, you must have a secondary specialized education. You can, of course, simply get a job at a factory and take a “young fighter” course and get a certificate stating that you are a turner.

It is also necessary to have a good reaction, a clear head and good ability to read drawings and other technological documentation. Well, you’ll learn the rest :)

What kind of profession is a turner? Conclusion

And so let's sum it up. What kind of profession is a turner? This is what we were talking about today, but whether to choose this specialty for yourself or not is up to everyone to decide for themselves :) See you soon! And by the way, don't forget subscribe to updates my engineering blog :)

Andrey was with you!

Profession carousel turner– one of the leading specialties in engineering industry. The product of the work of a carousel turner is products that have a cylindrical or conical shape with holes, grooves and various types thread. The dimensions of the parts can be different - from a few mm to several meters.

Features of the profession of a carousel turner

A carousel turner is a worker who works on a carousel machine and specializes in turning, in which there is nothing to do. Machining of a part is carried out through the interaction of a workpiece in rotation and a cutting tool moving at a given speed at certain angles.

A carousel turner must have the following qualities: imaginative technical thinking, spatial imagination, precise coordination of hand movements, attentiveness, the ability to concentrate, accuracy in work, and a creative attitude to the process.

All the danger and complexity of the work lies in the machine operating on high voltage. In addition, the equipment contains metal, hot, rapidly rotating elements. Therefore, at the workplace, the rotary turner must pay special attention to compliance with safety regulations. Risk exists everywhere, and in this case it is well paid.

Pros of the profession: work indoors with good lighting, high wages. Disadvantages of the profession: shift work, heavy physical exertion, psychological stress due to noise, metal dust and oil vapors in the air. This specialty is not suitable for people with hypersensitive skin, visual defects, chronic diseases of the musculoskeletal and cardiovascular systems, as well as the respiratory system. Therefore, the choice should be made carefully so that you don’t have to do it later.

Responsibilities of a carousel turner

Types of work of this specialist:

- processing of complex workpieces on specialized equipment or on a rotary machine using fixtures and tools;

- precise turning, boring of holes;

- thread cutting;

- turning cylindrical (conical) surfaces using several cutting tools;

- plasma-mechanical processing of workpieces;

- processing of solid-rolled wheels to a given size after rolling.

The specialist must know the structure of rotary turning equipment, plasma installations, universal devices, roughness parameters, sharpening rules, as well as the properties of the materials being processed.

04.10.2013

02.10.2013

02.10.2013

Tariff and qualification characteristics of the profession “Carousel turner” are required to determine the types of work tariff rate and assignment of ranks in accordance with Article 143 of the Labor Code of the Russian Federation.

Based on the specified characteristics of the work performed and the requirements for professional knowledge and skills, a job description for a carousel turner is drawn up, as well as personnel documents, including for conducting interviews and testing for employment.

When drawing up work (job) instructions, it is necessary to take into account general provisions and recommendations for the release of ETKS 2, if there is not enough information, please search for a profession through the catalog of professions and specialties in alphabetical order.

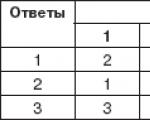

§ 117. Carousel turner 2nd category

Characteristics of work. Turning of simple parts and products according to 12 - 14 qualifications on rotary lathes using cutting tools and universal devices. Installation of parts into a chuck or faceplate with alignment using a square and surface planer. Control of rotary lathes with a faceplate diameter from 4000 to 9000 mm under the guidance of a more highly qualified rotary lathe operator.

Must know: design and principle of operation of similar rotary lathes; name, purpose and conditions of use of the most common universal devices; arrangement of control and measuring instruments; the purpose and rules for using a cutting tool, its main angles and rules for sharpening and installation; system of admissions and landings; qualities and roughness parameters; purpose and properties of cooling and lubricating fluids.

Examples of work

1. Runners (rollers) with a diameter of up to 750 mm - pre-treatment.

2. Gear rings - preliminary turning of the outer diameter and boring of holes.

3. Cylindrical bushings, flanges and rings with a diameter of up to 750 mm - pre-processing.

4. Bottoms and covers of tanks, boilers with a diameter of up to 750 mm - trimming the end and chamfering.

5. Wheels with a hub length of up to 500 mm - preliminary grooving and boring.

6. Piston rings, cylindrical gears, smooth pulleys, couplings and rims - pre-processing.

7. Mold extensions and trays for blind molds - trimming the ends.