POULTRY MEAT– CONTAINS CARCASSES AND PARTS

Gutted carcasses of chickens, ducks, geese, turkeys, guinea fowl,

DOMESTIC QUAIL

ASSORTMENT

Depending on their age, birds are divided into:

- YOUNG POULTRY MEAT. Young poultry meat includes carcasses of chickens, broiler chickens, ducklings, goslings, turkey poults and guinea fowl with a non-ossified (cartilaginous) keel of the sternum, with a non-keratinized beak, and with soft, elastic skin on the carcass. On the legs of chicken carcasses, broiler chickens, turkey poults and guinea hens there are smooth, tightly fitting scales and undeveloped (in the form of tubercles) spurs; Ducklings and goslings have delicate skin

- ADULT POULTRY MEAT

CLASSIFICATION AND CHARACTERISTICS

ASSORTMENT

Depending on the temperature in the thickness of the pectoral muscles, carcasses are released:

- in a cooled state (temperature no higher than 25 °C),

- chilled (temperature 0...4 °C),

- frozen - with a temperature from minus 2 to minus 3 ° C,

- frozen (temperature not higher than minus 8 °C),

- deep frozen at a temperature not exceeding minus 18 °C.

In the standards adopted later: GOST R 53458 2009 "Turkey meat (carcasses and parts). General technical conditions", GOST R 54376-2011 "Duck meat (carcasses and parts thereof). Specifications"Frozen meat has a temperature no higher than minus 12 °C; there is no frozen meat.

Based on fatness and quality of processing, carcasses of all types of poultry (except chickens) are divided into two grades

:

- FIRST

- SECOND

When determining fatness, muscle development (by highlighting the keel of the sternum) and the presence of subcutaneous fat are taken into account.

CLASSIFICATION AND CHARACTERISTICS

ASSORTMENT

Based on the method of processing, poultry carcasses are divided into:

- GUTTED. All gutted carcasses have been removed internal organs, head (between the 2nd and 3rd cervical vertebrae), neck (without skin) at the level of the shoulder joints, legs to the tarsal joint or below it (no more than 20 mm); visceral fat from the lower abdomen has not been removed; The presence of lungs and kidneys is allowed.

- GUTTED WITH A SET OF GIVINGS AND NECKS. The liver, heart, gizzard, neck (without skin) are processed, packaged in a polymer film approved by the authorized body for contact with this product, and placed in the cavity of the carcass.

CLASSIFICATION AND CHARACTERISTICS

ASSORTMENT

Products for cutting gutted carcasses:

- The leg of a poultry carcass is the femur and tibia with adjacent muscle, connective and fatty tissues.

- Femur - the femur with adjacent tissues.

- The lower leg is the tibia and tibia with adjacent tissues.

- Breast - the breastbone with adjacent tissues.

- Fillet - pectoral muscles separated from the bone.

- Wing - humerus, ulna, radius and hand bones with adjacent tissues.

- The humeral part of the wing is the humerus with adjacent tissues.

- The ulnar part of the wing is the ulna, radius and hand bones with adjacent tissues.

- The bird's neck consists of cervical vertebrae with adjacent tissues, without trachea and esophagus. The processed bird's neck may be without skin.

- Poultry carcass is part of a gutted bird carcass after the legs, wings and fillets have been separated.

- The tail is a part of a bird carcass, consisting of the caudal vertebrae and adjacent tissues and the coccygeal gland.

CONSUMER PROPERTIES

Lean poultry meat (chicken, turkey) is not inferior in content of complete proteins and even surpasses the muscle tissue of beef. Poultry meat (except geese) has about half as much connective tissue as beef and lamb.

- Amount of proteins in poultry meat (%): 17-17.2 - second-class geese and ducks; 21.3-23.6 - chicken and chicken fillet; 18.5-21.7 - turkeys and turkey poults of the first and second grade; 15.2-15.8 - first grade geese and ducks.

- Fat content (%): 38-39 - first grade geese and ducks; 1.9-2.5 - chicken and chicken fillets; 16.1-18.4 - hens and broiler chickens of the first grade.

In chickens and turkeys, the pectoral muscles are white, the rest are red. In a waterfowl, all the muscles are red. Red muscles contain significantly more fat than white muscles; for example, chicken legs and chicken legs contain 5.5-6 times more fat than poultry fillets. Imported chicken legs, as a rule, are fattier than domestic ones, but with the introduction of intensive methods in poultry farming, this difference is reduced.

CONSUMER PROPERTIES

- Poultry fat is fusible, 2/3 of the fatty acids it contains are unsaturated. The proportion of polyunsaturated (essential) fatty acids (linoleic and arachidonic) in poultry meat is 5-20 times greater than in beef and lamb. The cholesterol content is almost the same as in the meat of slaughtered cattle.

- In terms of phospholipid content, chicken does not differ from beef of the second category, but there are 2.5 times more of them in broiler meat; there are even more phospholipids in second-grade turkey meat (4 times more than in second-grade chicken).

- Compared to the meat of slaughtered cattle, poultry meat contains slightly more vitamin B6 and 2 times more biotin.

- In terms of phosphorus content, poultry meat does not differ from the meat of slaughtered animals, but contains less iron and zinc (1.5-2 times), as well as potassium - by about 30%.

FACTORS FORMING

CONSUMER PROPERTIES

Lifetime factors influencing the formation of consumer properties of poultry meat are the same as for slaughter animals: type of bird, age, gender (old roosters, although not highlighted in the current standard, have worse consumer properties) . Meat broiler chickens obtained in recent years from crossing special meat lines and breeds with intensive fattening, they reach a weight of more than 1 kg already at the age of 40~35 days, which made it possible to reduce prices for this high-protein product. It should be noted that its flavor and aromatic properties have decreased.

Both when growing poultry and when processing it, strict veterinary control is required. A feature of poultry processing is the widely used method of cooling carcasses in ice water. To reduce the risk of cross-contamination of carcasses infectious diseases both in the domestic poultry processing industry and abroad, in particular in the USA, chlorine was used as a preservative in significant quantities. In 2008, domestic sanitary authorities banned the use of chlorine as a preservative. In subsequent years, contracts were concluded only with those American enterprises that abandoned chlorine, although this does not mean that preservatives are not used at all.

FACTORS FORMING

QUALITY

Until 2008, GOST 21784-76 was in full force for the meat of the main types of poultry, which is now gradually being replaced by national standards for each type of poultry meat. It has not yet been processed into guinea fowl meat. IN national standards quality and classification requirements are more harmonized with international standards. The first and second categories have been replaced by 1st grade and 2nd grade, which depend on the fatness and quality of carcass processing.

Carcasses that meet the fatness requirements of grade 1 and quality of processing - grade 2, are classified as grade 2. In chicken meat, chicken carcasses (from egg-laying breeds) in trading network are not supplied, are not divided into grades and are used only in industrial processing. The meat of broiler chickens (meat productivity direction) goes on sale and is divided, like chicken meat, into 1st grade and 2nd grade.

FACTORS FORMING

QUALITY

Quality and safety requirements

For class 1 poultry carcasses, single stumps are allowed, sparsely scattered over the surface of the carcasses; and for grade 2 - a small amount of stumps sparsely scattered over the surface of the carcass. For all names, bumps on the keel of the sternum in the stage of mild skin thickening, as well as pinpoint hemorrhages, are acceptable. In grade 2 poultry carcasses, as well as chickens, a slight curvature of the keel of the sternum and the absence of the last segments of the wings are allowed.

Poultry carcasses and parts thereof must meet the following minimum requirements:

- well bled, clean;

- without foreign inclusions (for example, glass, rubber, metal);

- without foreign odors;

- free of fecal contamination;

- no visible blood clots;

- without remains of intestines and cloaca, trachea, esophagus, mature reproductive organs;

- without cold burns, stains from spilled bile.

FACTORS FORMING

QUALITY

Quality and safety requirements

Carcasses are not allowed for sale, but are sent only for industrial processing for the production of food products:

- 2 grades that do not meet the processing quality requirements;

- poorly bled;

- with bruises;

- with the presence of pronounced namins requiring removal;

- with scratches on the back;

- with fractures of the tibia and wings, in the presence of exposed bones;

- with curvatures of the back and chest bone;

- having dark pigmentation.

For turkeys and guinea fowls, dark pigmentation is allowed.

The mass fraction of moisture released during defrosting of all types of poultry meat should not exceed 4.0%. This indicator is determined in the event of visual detection of ice in the packaging and/or inside the product (for example, carcass, hind quarter).

FACTORS FORMING

QUALITY

Quality and safety requirements

For sale, poultry meat is produced in consumer packaging. There are several parts of carcasses in a package, one carcass. Group packaging is allowed for catering and industrial processing.

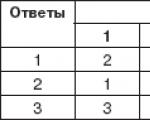

Requirements for freshness indicators of poultry meat are presented

:

- according to organoleptic indicators;

- microscopic and microbiological indicators.

The same safety indicators have been established for poultry meat as for meat from slaughtered animals.

FACTORS PRESERVING

QUALITY

Expiration dates are set by the manufacturer.

Cooled poultry meat cannot be transported or stored.

- The shelf life of chilled chicken and turkey carcasses is no more than 5 days, parts of carcasses - no more than 2 days. from the day of production at temperature conditions: for chickens - from 0 °C to 1 °C inclusive, for turkeys - from minus 1 °C to 2 °C inclusive.

- The shelf life of frozen chicken and turkey meat at an air temperature not higher than minus 18 °C: carcasses in consumer packaging - no more than 12 months, in group packaging - no more than 8 months; parts of carcasses - no more than 3 months. At minus 25 °C, the shelf life increases, at a temperature of minus 12 °C, it decreases significantly.

- Guinea fowl carcasses are stored at minus 18 °C for up to 14 months, which indicates their better preservation when frozen compared to other types of poultry.

In the store, the shelf life of poultry carcasses of all types at temperatures from 0 to 6 °C is up to 3 days; at a temperature not higher than 8 °C, chilled poultry is stored for 24 hours, and frozen poultry is stored for up to 2 days.

Mechanical culinary processing of meat Beef, pork, lamb Defrosting Slow 0 0 C to C from 1-3 days Slow 0 0 C to C from 1-3 days Fast From h Fast From h Cutting off the brand and cleaning the surface from dirt Washing carcasses Drying Cutting up carcasses Dividing into cuts Deboning cuts

After defrosting, the meat is cleaned of dirt, blood clots and the veterinary mark is cut off, the carcasses are washed with water at a temperature of C using brushes and then with cold water at a temperature of C, the carcasses are dried with circulating air at a temperature of 1-6 C or cotton fabric. Cutting carcasses - dividing into cuts, deboning, trimming, separating large-piece semi-finished products and cleaning them. Boning is the separation of the muscle and connective tissue of the carcass from the bones. Trimming – removal of small bones, cartilage, tendons, and excess fat from the pulp. Cleaning - removing films, giving the pieces the appropriate shape. Carcasses are cut at a temperature of 10 C. If the meat comes in half carcasses, then they are divided between the 13th and 14th vertebrae into two quarters - fore and hind.

Forequarter Hindquarter Cut Semi-finished productsCut Semi-finished products - Neck - Shoulder - Dorsal-thoracic 1 - shoulder part 2 - shoulder part 3 - subscapular part 4 - thick edge 5 - hem 6 - brisket - Lumbar - Hip 7 - thin edge 8 - tenderloin 9 - flank 10 – top part 11 – side part 12 – outer part 13 – inner part Beef carcass cutting diagram

Lumpy semi-finished products - pieces of pulp, consisting of one or more large muscles, have a mass of 1.5-2 kg Portioned semi-finished products - pieces of pulp of a certain shape, size and weight, cut across the muscle fibers from certain large-lump semi-finished products and subjected to additional technological processing. Portioned semi-finished products are divided into natural and breaded, weighing from grams. Small-piece semi-finished products are pieces of pulp weighing 5-40 g, of a certain size and shape, cut across muscle fibers from large-piece semi-finished products characterized by a certain ratio of muscle and connective tissue. Chopped semi-finished products are culinary products of a certain shape, size and weight, made from chopped cutlet meat. Chopped semi-finished products are divided into natural and cutlet mass. In cutlet mass, bread is mainly used as a filler. Chopped semi-finished products can be breaded or unbreaded.

General rules preparation of semi-finished products: 1) Cutting - carried out across the fibers, as it contributes to less deformation during heat treatment. 2) Sequence when cutting semi-finished products: large pieces, portions, small pieces. 3) Semi-finished products containing a significant amount of connective tissue are subjected to the following operations: loosening, beating, which weakens the strength of the connective tissue layers and reduces the cooking time. 4) Marination - to soften meat, food acids and enzymes are used, the meat softens because collagen swells and its taste changes. 5) Breading - to improve the quality and expand the range of products.

Prepared from the upper, inner, side and outer pieces of the hip part weighing 1.52 kg. The meat is cleaned and stuffed along the grain (or at an angle of 45°) with carrots, white roots, bacon, and cut into long pieces. Cooled lard is injected into the meat using a lard needle. I use it for stewing and baking SPIRED MEAT

STORAGE TIME At a temperature of 6 0 C no more than 48 hours QUALITY REQUIREMENTS surface of pieces unweathered surface of pieces unweathered color and smell - benign meat color and smell - benign meat no coarse tendons, cartilage, bruises no coarse tendons, cartilage, bruises STORAGE CONDITIONS OF LARGE PIECES SEMI-FINISHED OB

Cut from thick, thin edges stripped of fat and coarse tendons in the form of an irregular round or oval oblong shape, cut in the transverse direction to the location of the fibers, 1.5-2 cm thick, beaten. Tendons and films are cut Type of heat treatment - frying (ENTRECOTE

Cut at an angle from the thin part of the tenderloin (tail), two pieces per serving, 11.2 cm thick. The semi-finished product is lightly beaten. Type of heat treatment - frying Langet

Cut from the side and outer pieces of the hip part, 11.5 cm thick, beat it, put minced meat in the middle, roll it into sausages and tie it with thread or twine. For minced meat: sauteed onions are combined with boiled chopped eggs or mushrooms, parsley, ground breadcrumbs; add salt, pepper and mix. Type of heat treatment - stewing ZRAZY CHOPS

Cut from thick and thin edges, upper and inner pieces of the hip part, 1.5-2 cm thick, beat, cut the tendons, sprinkle with salt, pepper, moisten in lezone, breaded in red breading, give shape. Type of heat treatment - frying rump steak

STORAGE LIFE QUALITY REQUIREMENTS Sliced across the grain Sliced across the grain The surface of breaded semi-finished products is completely covered with breading, torn and broken edges are not allowed the color and smell of good-quality meat The surface of breaded semi-finished products is completely covered with breading, torn and broken edges are not allowed color and smell of good-quality meat are absent rough tendons, cartilage, bruises no rough tendons, cartilage, bruises At a temperature of 6 0 C Natural no more than 36 hours Breaded no more than 24 hours STORAGE CONDITIONS OF SEMI-PORTIONED PRODUCTS

Cut from the tenderloin, thick and thin edges, top and inner pieces of the hip. From a large piece, portion pieces with a thickness of 1-1.5 are cut across the fibers, beaten to a thickness of 0.5 cm, cut into cubes 3-4 cm long, weighing from 5 to 7 g. Type of heat treatment - frying BEEF STROGANOV

Cut portions 1.5-2 cm thick from the side and outer pieces of the hip part, cut into cubes 3-4 cm long, weighing g. Type of heat treatment - stewing ASU

Cut from the thick and thin edges, from the upper and inner pieces of the hip part into pieces 2 cm thick, beat and cut into cubes weighing g. Type of heat treatment - frying ROASTING

From the pulp of the shoulder and subscapular parts, brisket, trim, into pieces in the form of cubes weighing g. 4-5 pieces per serving. Fat content should not exceed 10%. Before cutting the semi-finished product, large pieces of the surface film are not peeled off. Type of heat treatment - stewing GOULASH

From the tenderloin, cut into pieces weighing 1 g, lightly beat, sprinkle with salt, pepper and stick on a skewer interspersed with pieces of lard, cut into squares, onions into circles. Place on a skewer, alternating meat, lard, and onion. Type of heat treatment - frying MOSCOW STYLE SHAB

Storage conditions for small-piece semi-finished products CONDITIONS AND DURATION OF STORAGE At a temperature of 6 0 C no more than 24 hours QUALITY REQUIREMENTS QUALITY REQUIREMENTS color and smell - good quality meat color and smell - good quality meat no coarse tendons, cartilage, bruises no coarse tendons, cartilage, bruises Sliced across the grain Cut across the grain

Types of meat

Animal meat :

Beef

Veal

Mutton

The meat is a combination various types fabrics -

Proteins 14-20%

Connective

Minerals (phosphorus, calcium, sodium, magnesium, iron salts)

Muscular

Vitamins A, D, PP, B.

Beef

It has a red color with various shades. In this case, the color depends on the age of the animal: the older, the darker its meat.

The meat of adult cows (3-7 years old) is bright red.

Young meat – up to 3 years – is pale pink with white fat.

Veal

Veal is the meat of milk-fed calves aged 2 to 10 weeks. It has a light pink color. The consistency is delicate, the smell is sweet and sour. Absorbs better than the meat of adult animals. Veal dishes are good for children.

Pork

Pork is characterized by a pale pink color of various shades, a delicate soft consistency with a layer of fat.

Piglet meat – light pink, tender, tasty, with white fat

MUTTON

Lamb has a color from light to dark red and has a specific smell. The meat of wool sheep gives off a faint odor of sweat.

Lamb meat is more tender and odorless, pale pink, the fat is white and dense.

Signs of good quality meat:

The meat is covered with a thin crust of pale pink or pale red color. When touching the surface, the hand remains dry. When cut, the meat does not stick to your fingers.

The color of the meat is pale pink to red, the juice is clear.

The consistency of fresh meat is dense. If you press on it with your finger, a hole is formed, which quickly levels out.

The smell is specific meat.

Thermal state of meat:

- paired (obtained immediately after slaughter)

- cooled (kept in natural conditions for 6 hours)

- chilled (t 0...+4)

- frozen (t -6...-8)

Primary meat processing

Characteristic

Thawing

(if the meat is frozen)

The temperature of the meat should increase slowly, then as it thaws, the meat juice is absorbed by the muscle fibers and the loss of nutritional value of the product decreases.

Washing

The meat is washed with water, and the fatty areas with warm water.

Drying

Dried meat is easier to cut. Drying prevents the proliferation of microbes. The meat is dried in air or by blotting with a cotton napkin.

Cutting

Cutting a large piece of meat or a whole carcass into separate parts allows you to use everything correctly

Separating the flesh from the bones is called deboning. The waste that is generated after deboning (bones, tendons, cartilage) can be used to prepare broths.

Meat sorting, tendon separation

Scheme for cutting beef carcass:

1.

spatula (A. shoulder, b. shoulder part); 2.

neck; 3.

thick edge; 4.

hem; 5

. brisket; 6.

thin edge; 7

. tenderloin; 8.

flank; 9.

pelvic part ( G. top, d. outdoor, e. internal, and. lateral_.

Scheme for cutting lamb and pork carcasses:

1. shoulder blade

3. loin

4. brisket

- The resulting pieces of pulp are cleaned of tendons, coarse films, excess fat and semi-finished products are obtained.

Semi-finished products

is a product that has undergone primary processing and needs further development

Portioned semi-finished products

- steak

- splint

- entrecote

- rump steak

- for baking

Portioned semi-finished products

Chops - a piece of oval-flat flesh with a bone, breaded in breadcrumbs

Beefsteak is a piece of irregularly rounded flesh 2…3 cm thick

Entrecote is a piece of oval-oblong shaped pulp 1.5...2 cm thick

Small-piece semi-finished products

7. beef stroganoff

9. frying

Small-piece semi-finished products

Shashlik -

weight of meat

weighing 20...30 g

Beef Stroganoff –

sticks of meat

3...4 cm long,

weighing 5...7 g

Products from chopped mass

A. cutlets

b. bits

in schnitzels

g. meatballs

e. rolls

Semi-finished products from chopped mass

Chopped semi-finished products - cutlets

Chopped mass

Cooking - This is the heating of food in liquid.

Steaming(in special cabinets or on bars).

Frying - This is heating a product without liquid in varying amounts of fat.

Grilled(roasting over an open fire).

Extinguishing

The meat is pre-fried or boiled until half cooked, then placed in a saucepan, sauteed vegetables are added, poured with water or broth and simmered under a closed lid.

Baked and baked meat

Meat for roasting should be first-class, without rough films and tendons, and not too fatty, since too fatty meat causes too much loss during cooking.

Types and condition of meat

Types of meat

Signs of good quality meat

Beef:

Operations machining meat

- Meat from an adult cow (3-7 years old)

- Young meat

- (from 3 months to 3 years)

- Veal (2 weeks – 3 months)

- There is a special brand

- Color: when cut – reddish with shades depending on the type of meat, fat is white, cream or yellowish

- The juice is clear.

- Smell: specific meaty

- Consistency: thick,

Pork

Thermal state of meat

elastic meat, hard fat.

- Defrosting

- Washing, cutting off marks

- Drying,

- Razrub

- boning,

- Stripping

- Zhilovka

Mutton

- Pairs

- Cooled down

- Chilled

- Ice cream

- Supercooled

- Thawed

- Thawed

Plan: 1. Characteristics and nutritional value of raw materials. 2.Mechanical culinary processing of poultry and game in enterprises that use raw materials. 3. Production of semi-finished products. 4.Manufacture of products from cutlet and dumpling mass. 5.Centralized production of semi-finished products. 6. P/f from rabbit. Plan: 1. Characteristics and nutritional value of raw materials. 2.Mechanical culinary processing of poultry and game in enterprises that use raw materials. 3. Production of semi-finished products. 4.Manufacture of products from cutlet and dumpling mass. 5.Centralized production of semi-finished products. 6. P/f made of rabbit.

The bird arrives at the processing facility different types(chickens, hens, ducks, geese, turkeys) Poultry arrives at the processing facility of different types (chickens, hens, ducks, geese, turkeys) - first and second categories of fatness, - cooled, chilled or frozen, - gutted or semi-gutted. In semi-gutted carcasses, feathers, intestines, and blood have been removed; and in gutted ones - all the internal organs, head, neck, paws.

Poultry meat contains proteins, fats, vitamins, minerals and extractives, water, and is highly valuable food product. The content of basic substances depends on its fat category, type and age. There is significantly less fat in the meat of young poultry and game than in the meat of adults. Poultry meat of different species differs significantly in chemical composition. Thus, high protein content is typical for turkey meat (19-21%) and chicken (18-21%), fat content is typical for geese and duck meat (24-39%). Game meat contains more proteins (23-25%) and less fat (1-2%), with the exception of quail (proteins-18%, fats-18.6%). Chicken and turkey meat is lighter in color than waterfowl meat. The color of the muscle tissue of chickens and turkeys is different: the breasts and wing muscles are white, while others are dark red. The color of the muscles of waterfowl does not depend on location. The nutritional value of white meat is higher than red meat due to its higher protein content and a more favorable ratio between complete and incomplete proteins. Dark meat has more fat than white meat. Poultry meat contains less connective tissue proteins than meat from slaughtered animals.

1. Defrosting. In a cooled room at T=8C and relative air humidity of 90-95% for an hour. Feathers are removed from thawed game carcasses by plucking, starting from the neck. To avoid damaging the skin, it is slightly pulled back. 2. Searing. Using a gas torch on a flexible hose. Game is singed only when, after plucking, lint and fine fluff remain. The stumps are removed with tweezers. 3. Removal of heads, necks and paws. The head is cut off at the second cervical vertebra. Before removing the neck, a longitudinal incision is made in the skin from the back, then the skin is shifted, the neck is freed and it is cut off, 5-6 cm of skin is left to cover the cut site. After this, the esophagus, trachea and crop are removed. For small game - snipe, great snipe, woodcock - the heads are not cut off, but the skin is removed from them and from the neck and the eyes are removed. Then the wings are cut off at the elbow joint and the paws are cut off 1-2 cm below the knee joint. 4. Gutting. In a semi-gutted bird, the internal fat (omentum), liver with gall bladder, stomach, heart, kidneys, lungs, spleen, ovaries, oviduct are removed; in a gutted one - omentum, lungs, kidneys. Gutted through a hole in the abdominal cavity from the anus to the keel of the sternum. To gut small game, cut the neck from the back. Pieces of carcasses soaked in bile are cut off.

Chickens, chickens, turkeys are tucked into two threads, which are fried; for boiling, this bird is tucked into a pocket. Game (except small ones) is tucked into one thread; geese, ducks, turkeys, tucked into a pocket. Small game is dressed without twine. In quails, an incision is made on one leg, closer to the knee joint, between the bone and the tendon and the second leg is inserted into it. Grouse, black grouse, wood grouse, pheasants are tucked into one thread. The meat of black grouse, wood grouse, pheasants, and partridges is not juicy enough, so it is stuffed after seasoning. Before stuffing them for 3-5 minutes. immersed in hot water (60-70C), which facilitates the stuffing process by compacting the fabric and improves appearance carcasses. The main product is a cut-up and processed carcass. It is used entirely for cooking and frying, as well as for making semi-finished products for poaching, stewing and frying. 6. Processing of offal. The gallbladder is cut off from the liver along with a small part of the liver tissue so as not to damage the bladder. The cuticle of the stomach is removed. To do this, the stomach is cut in the middle and turned inside out. inside outwards, after which the cuticle is removed. The heart is cut open and freed from blood clots. Giblets (except liver) are washed in cold water, no higher than 15C. Poultry food waste includes heads, necks, feet, combs, wings, livers, gizzards and hearts; Only necks are included in game food waste.

In chickens, much less in pheasants, hazel grouse, grouse and partridges, fillets are removed to make cutlets and schnitzels (natural). The carcasses are placed with their backs on the table, cuts are made in the flanks and the skin is removed from the pectoral muscles, then they are cut off from the breast bone and cut clavicle and remove the right and left muscles (fillet) along with the humerus bones; the removed pectoral muscles are cleaned. In this case, the inner muscle (small fillet) is separated from the outer muscle (large fillet). The tendon is removed from the small one, and the remainder of the clavicle is removed from the large one. The humerus is cleared of pulp and tendons and shortened to 3-4 cm, cutting off approximately half of the head of the shoulder joint. Next, the film is cut from the large fillet, and 1-2 small oblique cuts are made on the inside along the inside and the fillet is unfolded so that its tendon is exposed inside, which is cut in 2-3 places, after which the fillet is shaped.

Fillet cutlets are made stuffed and unstuffed. For poultry fillet cutlets, butter (Kiev cutlets) or thick milk sauce is used as minced meat, and for game fillet cutlets, pate or dumpling mass is used. Unstuffed cutlets are made natural or breaded, stuffed cutlets are made only breaded.

To make stuffed cutlets, the cleaned large fillet is cut lengthwise, turned in both directions, then lightly beaten with a hoe to a thickness of 2-3 mm and trimmed in 2-3 places. Chopped pieces of meat cut from small fillets are placed on the cuts. Place cooled minced meat in the middle of a large fillet, cover it with small beaten fillets, and fold the edges of the large fillet, giving the cutlet a rounded pear-shaped shape. The cutlets are sprinkled with salt, dipped in lezone and breaded in bread crumbs. Kiev cutlets are breaded twice so that the oil does not leak out during frying. In addition to fillets, we get legs, wings (fried), trimmings (for cutlet mass) and frames (for cooking broths).

The pulp of chickens, turkeys and big game is used. The technology for producing cutlet mass is the same as for making meat from slaughtered animals, only butter and oil seal are added. The products are cutlets and meatballs, but less than meat. The technology for producing dumpling mass is the same as for making fish. Used for stuffing game fillet cutlets and making dumplings of various shapes as a side dish for clear soups.

The pulp of chickens, turkeys and big game is used. The technology for producing cutlet mass is the same as for making meat from slaughtered animals, only butter and oil seal are added. The products are cutlets and meatballs, but less than meat. The technology for producing dumpling mass is the same as for making fish. Used for stuffing game fillet cutlets and making dumplings of various shapes as a side dish for clear soups.

Rabbit meat comes in fatness categories 1 (75% pulp) and 2 (70% pulp). Rabbit meat is a high-value protein product (21% protein), fat – 13%. It contains B vitamins, minerals and extracts. During mechanical processing, the carcasses are branded, the neck, cervical vertebra, and kidneys are removed, after which the carcasses are cleaned and cut into 2 parts - the front and back along the last cervical vertebra. The pulp of the back part contains little connective tissue, which is why natural cutlets and stuffed (with milk sauce) cutlets are made from it. The front part is used for stewing. Products from cutlet mass (cutlets, meatballs) are also made from rabbit meat. Prepared rabbit carcasses are used completely (boiling, frying) or for preparing portioned (natural cutlets, stuffed cutlets, capital-style rabbit), small-piece (stew, pilaf, amateur rabbit) and chopped (cutlets, meatballs) semi-prepared the same technology used to produce semi-finished products from poultry.